Ordinary one-way valve is referred to as a one-way valve. It allows the oil to flow in only one direction and does not allow reverse flow, so it is also called a check valve. Although the structure and working principle of the check valve are relatively simple, it is one of the most widely used components in the hydraulic system. Correct application of the check valve can not only meet the various functional requirements of the hydraulic system in different applications, but also simplify the design of the hydraulic system. OFF has sorted out the application scenarios of check valves in several commonly used hydraulic systems, and will give you a brief introduction.

1 Application of one-way valve

1.1 For system feeding oil

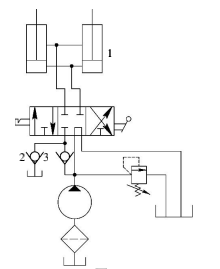

Figure 1 is a schematic diagram of a hydraulic system for lifting heavy objects. The check valve group is composed of check valves 2 and 3, which are used as the oil supply valve group of the hydraulic system. The function of the check valve 2 is to replenish oil: when the heavy object falls, the piston rod of the hydraulic cylinder 1 will drop rapidly under the action of the heavy object. At this time, the oil inlet chamber of the hydraulic cylinder will generate a partial vacuum due to insufficient oil supply. , and then the cavitation phenomenon occurs. Due to the drop in the pressure of the oil inlet chamber, under the action of the pressure difference, the check valve 2 opens, and the oil is replenished from the oil tank to the oil inlet chamber of the hydraulic cylinder, avoiding vacuum and making the hydraulic cylinder run smoothly. The function of the oil inlet check valve 3 is to prevent the oil from flowing backward. For example, when the engine suddenly turns off, the hydraulic pump stops supplying oil. At this time, the oil inlet check valve locks the hydraulic cylinder and keeps the weight in the original position. .

figure 1

1. Hydraulic cylinder 2. Oil charge check valve 3. Oil inlet check valve

1.2 Prevent oil circuits from interfering with each other

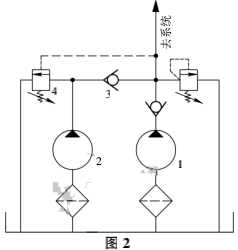

Figure 2 shows a dual-pump oil supply rapid motion circuit. The high pressure small flow pump 1 is used to realize the working feeding movement. The low-pressure high-flow pump 2 is used to achieve fast movement. During rapid movement, since the load is almost negligible, the system pressure is low, so the hydraulic control sequence valve 4 is closed, and the oil output by the hydraulic pump 2 and the hydraulic pump operator is combined to supply oil to the system to achieve rapid movement. During the working feed, the system pressure increases due to the large load. After the hydraulic control sequence valve 4 is opened, the hydraulic pump 2 is unloaded, and the oil flows directly back to the oil tank. The output pressure of the hydraulic pump 2 is extremely low, while the output pressure of the pump 1 is relatively large. At this time, the one-way valve 3 is closed, and the hydraulic pump 1 alone supplies oil to the system to realize the working feed. The existence of the one-way valve 3 separates the high-pressure and low-pressure oil circuits without interfering with each other.

1. High pressure small flow pump 2. Low pressure large flow pump 3. Check valve 4. Hydraulic control sequence valve

1.3 For direction selection

Figure 3 shows a closed circuit composed of a bidirectional variable pump 1 and a bidirectional motor 2, wherein the pump 3 is a charge pump. Check valves 4 and 5 are used as directional selector valves in the system for pump 3 to supply oil to the system. Check valves 4 and 5 are used in pairs and installed in opposite directions. No matter which side the oil outlet direction of the variable pump is on, it can always ensure that the hydraulic oil of the charge pump 3 can break through the resistance of the one-way valve and supply oil to the low pressure side of the circuit.

2 Conclusion

The one-way valve is the simplest type of hydraulic control valve, but it has a very wide range of applications and plays an irreplaceable role in the hydraulic system. As long as it can be used correctly, its function can be fully exerted, so that the hydraulic system The design has become simpler and more functional.