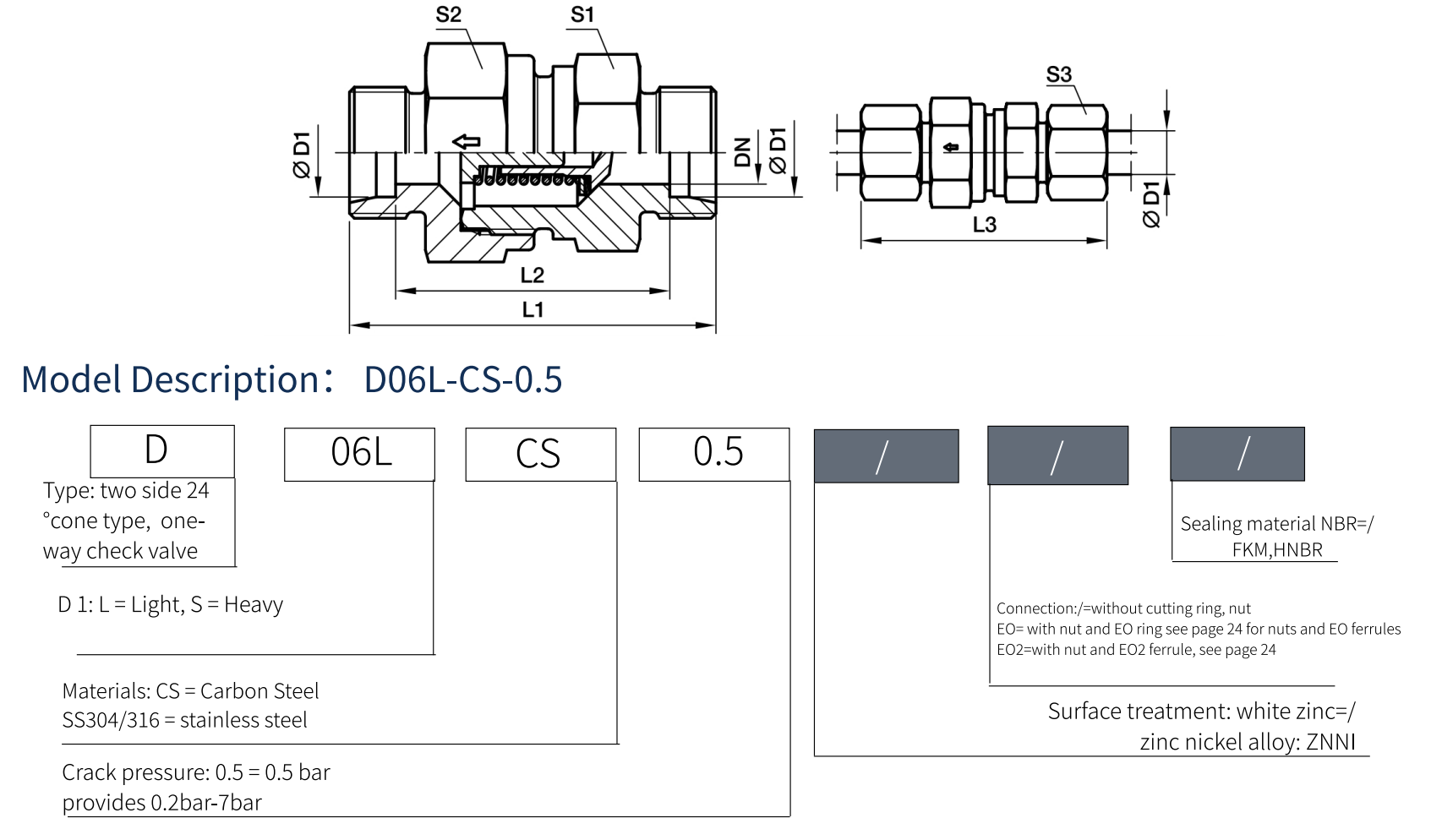

D Series-Softsealing-poppet-type-Tubulartypeone-way check valve

1. Structure and symbol

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||||||||||

| valve body | spool | sealing | gasket | adapter | Spring | O-ring | Spring seat | ||||||||||

2.Operation:

When pressure at①nises abowe the spring bias pressure,the poppetis lited and flowallowed from①to②.

The valve is closed (checked)from②to①

Match through 90"vave core and composite material seal ring and the valve cone seat torealize the seal.The walve core openingha the localization,therefore the opening is reliable,the vibrate is small,he noiseis low and the valve flow area is uniform distribution.The recommendation maximum flow speed does notsurpass8m/s(to enhanceflow speed need to pass through specially experiment)

2.1.Crack Pressures:The standand is0.5bar,can provide 0.2,0.7,1,2,3,4,5,6,7bar,he opening pressure changes in±20%permission

2.2 Ideal working temperature:NBR:-20°C-+90°C/FKM:-5°C-+180°C/HNBR:-40°C-+120°C

2.3 Installation torque refer to 4.Torque description,note:the body materialis carbon steel,and the screwed in partsare steel,For other materials,please contac auer engineer

2.4 0ilcleanliness:1504406:1999 standard4μM/5μM/14μM19/17/14

2.5 Auer provides a dampingoneway vave.Please contactAuers engineer for the size of the damping hole

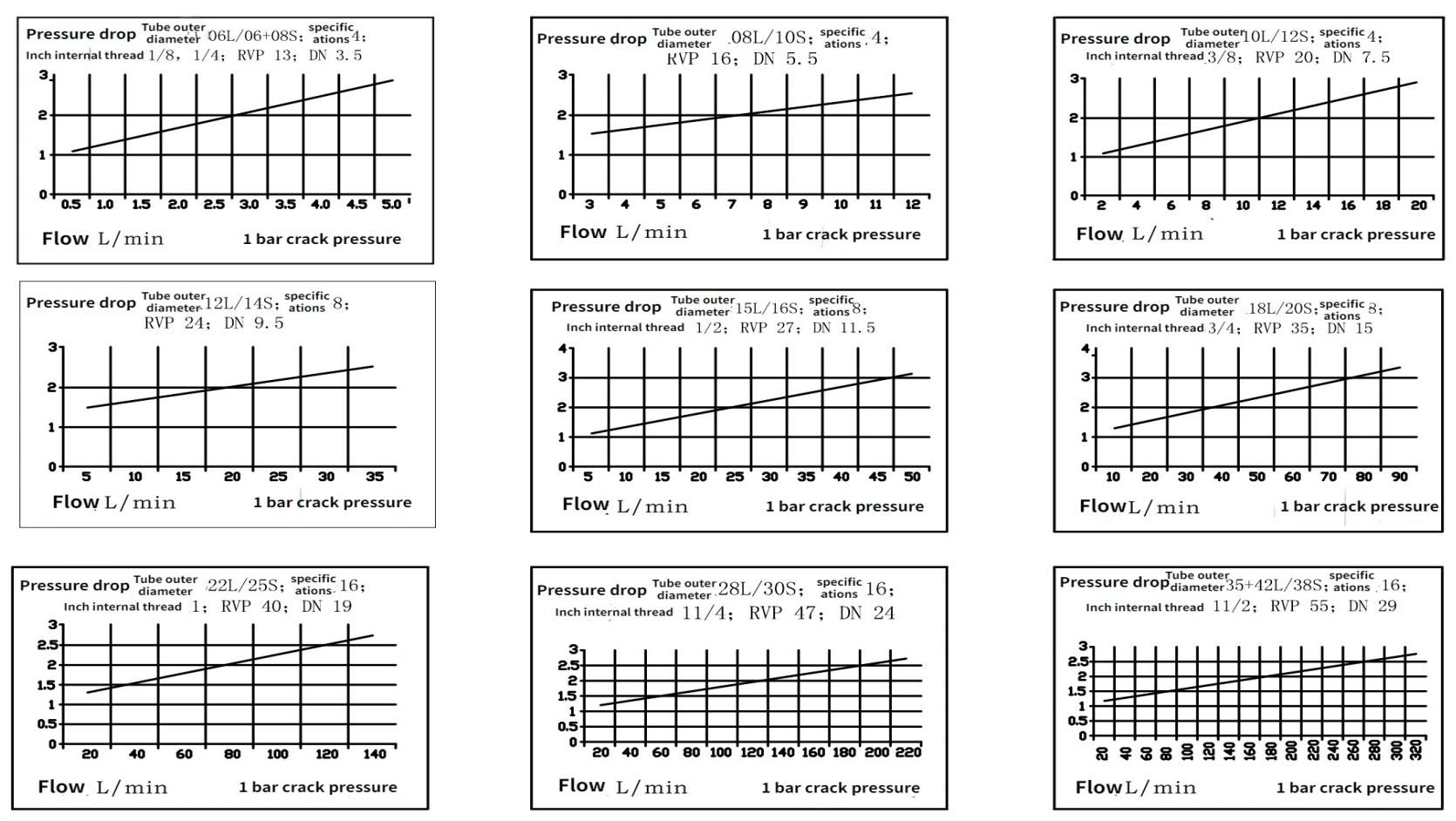

3.Pressure Drop VS. Flow

4.Data sheet

| CODE | THREAD | D1 | DN | L1 | L2 | L3 | S1 | S2 | S3 | TORQUE | W.T | W.P | ||

| [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm | [mm] | (N.m) | (g) | (bar) | ||||

| D06L | M12X1.5 | 06 | 3.5 | 43.0 | 29.0 | 58.0 | 17 | 17 | 14 | 15-25 | 46 | 400 | ||

| D08L | M14X1.5 | 08 | 5.5 | 44.0 | 30.0 | 59.0 | 19 | 19 | 17 | 20-35 | 61 | 400 | ||

| D10L | M16X1.5 | 10 | 7.5 | 55.0 | 40.5 | 69.5 | 22 | 24 | 19 | 25-40 | 104 | 400 | ||

| D12L | M18X1.5 | 12 | 9.5 | 58.0 | 43.5 | 72.5 | 27 | 30 | 22 | 30-45 | 166 | 400 | ||

| D15L | M22X1.5 | 15 | 11.0 | 62.0 | 47.5 | 77.5 | 27 | 32 | 27 | 40-70 | 192 | 400 | ||

| D18L | M26X1.5 | 18 | 14.0 | 67.0 | 51.5 | 83.5 | 36 | 41 | 32 | 60-100 | 292 | 400 | ||

| D22L | M30X2.0 | 22 | 18.0 | 77.0 | 61.5 | 93.5 | 41 | 46 | 36 | 100-135 | 472 | 250 | ||

| D28L | M36X2.0 | 28 | 23.0 | 85.0 | 69.5 | 102.5 | 50 | 55 | 41 | 150-240 | 746 | 250 | ||

| D35L | M45X2.0 | 35 | 29.0 | 96.0 | 74.5 | 117.5 | 60 | 65 | 50 | 260-360 | 1062 | 250 | ||

| D42L | M52X2.0 | 42 | 29.0 | 96.0 | 74.0 | 119.0 | 65 | 70 | 60 | 300-400 | 1518 | 250 | ||

| D06S | M14X1.5 | 06 | 3.5 | 48.5 | 34.5 | 63.5 | 19 | 19 | 17 | 20-35 | 70 | 420 | ||

| D08S | M16X1.5 | 08 | 3.5 | 48.5 | 34.5 | 63.5 | 19 | 19 | 19 | 25-40 | 74 | 420 | ||

| D10S | M18X1.5 | 10 | 5.5 | 55.5 | 40.5 | 72.5 | 22 | 24 | 22 | 30-45 | 121 | 420 | ||

| D12S | M20X1.5 | 12 | 7.5 | 57.5 | 42.5 | 74.5 | 24 | 27 | 24 | 35-45 | 148 | 420 | ||

| D14S | M22X1.5 | 14 | 9.5 | 64.0 | 47.5 | 82.5 | 27 | 32 | 27 | 40-70 | 218 | 420 | ||

| D16S | M24X1.5 | 16 | 11.0 | 68.0 | 50.5 | 86.5 | 32 | 36 | 30 | 50-80 | 286 | 420 | ||

| D20S | M30X2.0 | 20 | 15.0 | 76.0 | 54.5 | 97.5 | 41 | 50 | 36 | 100-135 | 506 | 420 | ||

| D25S | M36X2.0 | 25 | 19.0 | 83.0 | 58.5 | 106.5 | 46 | 55 | 46 | 150-240 | 639 | 420 | ||

| D30S | M42X2.0 | 30 | 24.0 | 97.0 | 69.5 | 122.5 | 60 | 60 | 50 | 260-360 | 1157 | 250 | ||

| D38S | M52X2.0 | 38 | 29.0 | 108.0 | 75.5 | 136.5 | 65 | 70 | 60 | 300-400 | 1650 | 250 | ||